Reducing Embodied Carbon in Facade Design

This decade is make-or-break in the fight for our environment. At Innovation Glass, we believe sustainability and decarbonization must inform every design and engineering decision we make.

While many sustainability efforts have focused on the "operational" carbon footprint of buildings—energy used for heating, cooling, and lighting—our industry is now also focusing on "embodied carbon," the carbon footprint of building materials. Our material choices and design decisions are key tools in the fight against climate change, and our team is committed to reducing the carbon footprint of facades around the world.

We are reducing the embodied carbon of VS1 facades by pursuing the following strategies: reducing framing material, prioritizing recycled content, material sourcing, and material choice.

Reducing Framing Material

VS1 eliminates horizontal metal, thereby reducing total framing material and increasing transparency. By using less framing material we reduce the overall embodied carbon of the facade.

Example: Loyola University Schreiber Center in Chicago. Designed by SCB. Completed in 2015.

Conventional Solution

Conventional Solution

VS1 Solution

VS1 Solution

OUR SOURCING:

US Extruders: 33% recycled content

European Extruders: 80% recycled content

Prioritizing Recycled Content

The majority of aluminum's embodied carbon comes from the smelting process. Recycled aluminum reduces embodied carbon by ~85%*, and aluminum is infinitely reusable. We are proud to source our aluminum from extruders that are increasingly using recycled content.

Material Sourcing

A material's origin impacts its embodied carbon:

Buy local: Transportation of building materials accounts for 5-15% of their footprint.*

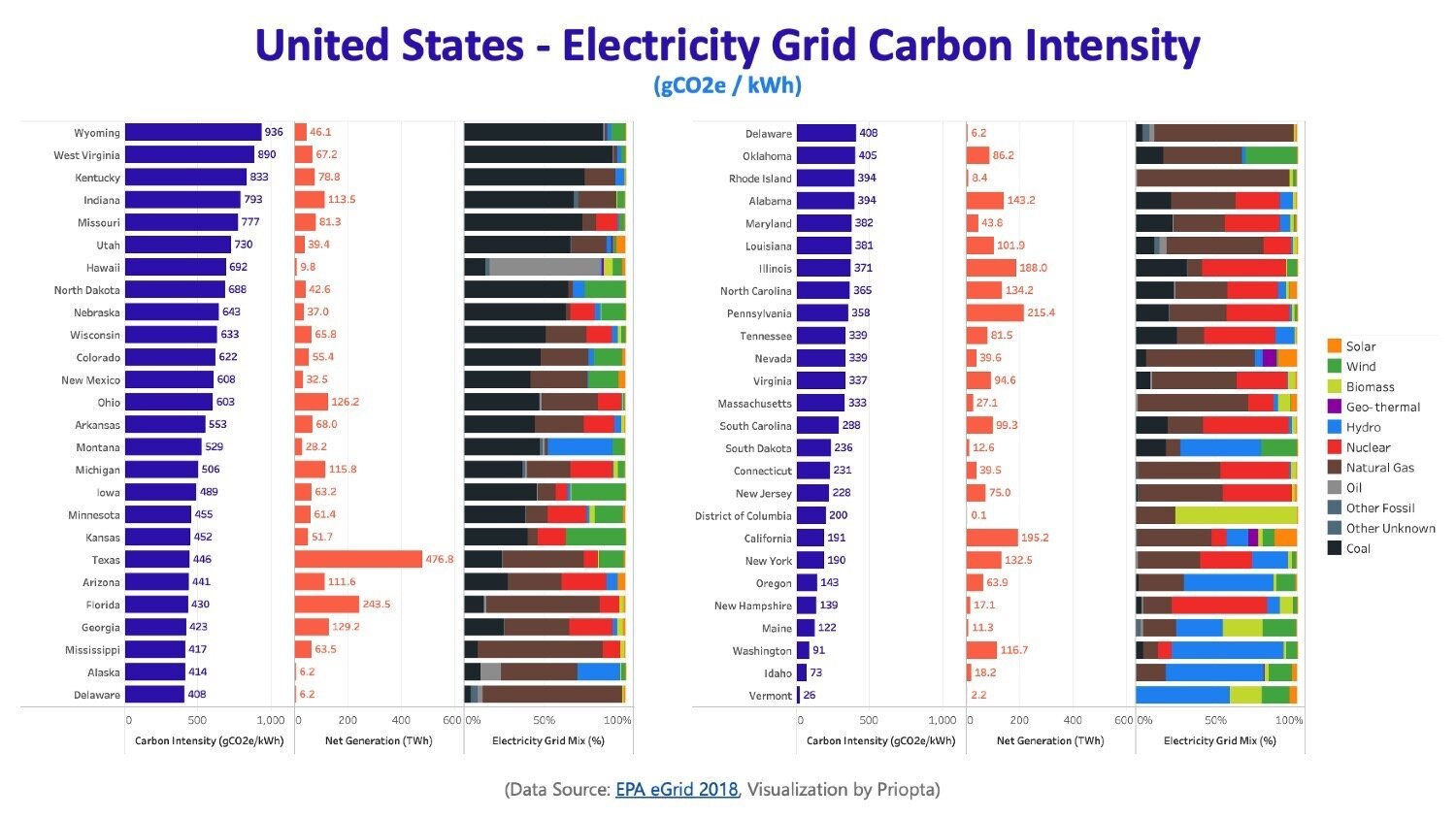

As seen in the graphic below, some regions have more climate-friendly power grids than others; green energy advocacy is a key strategy to reduce the embodied carbon of all building materials.

Material Choice

Finally, a key new strategy in reducing the embodied carbon in facade design is to transition to timber as a framing material. We are excited about this new opportunity for the following reasons:

Curtain walls are typically framed with steel or aluminum, which are high in embodied carbon.

Timber’s embodied carbon is 98% less than virginal aluminum, and can be harvested sustainably

In 2020 we developed VS1-t, a new hybrid timber curtain wall system. Like VS1, VS1-t can accommodate large spans with no horizontals. Custom profiles are available, as seen in the photo below. Timber is much lighter than aluminum, which will reduce shipping costs and allow for easier installation.